Peter was highly forthcoming and sent me detailed notes on the rig, which I reproduce with his permission here. (He doesn't have a web presence except on QRZ).

Although we spoke on 20m, the rig also does 80m, 40m, 30m and 20m. SSB and CW.

The rig uses a standard 8MHz IF strip that he's used in other projects. The VFO is a AD9913 DDS controlled by a Z80 microprocessor, but that bit is left to the reader...

The circuits are here RF, 8MHz IF, BFO, Crystal Oscillators, switching, and audio.

Here are Peter's build notes which will (eventually) be presented in three parts:

- The BFO or carrier oscillator Module

- The Crystal Filter Module. (mounted on the IF Board)

- The Complete IF module, RF to Speaker, Microphone to SSB (or CW send to RF Carrier generation)

I have a logical reason for presenting them in this order, the BFO Carrier Module is a stand alone boxed up module and will be a use full signal source for testing and debugging if you don't have a Signal Generator.

Some 50 Ohm step attenuators will be needed to use it as a signal generator for the IF strip, these are easily made, just three resistors, the ARRL handbooks gives values for PI and T network step attenuators of various dB values, and of course I'm sure you will find them on the Internet some where.

BFO or carrier oscillator Module

Please refer to the BFO circuit available here

The circuit is comprised of three distinct sections:

- Crystal oscillators

- Logic supply switching

- Supply regulators

The easy part first.

The supply regulators are three pin (through hole) regulators, a 78L05 regulator is used for the 5 Volt supply as it is only powering one 74HC00 IC (again through hole) with 3K3 pull up resistors and 5K6 output resistors there will be very little current drain from this device, well below the 100mA maximum of the 78L05.

The 7808 is probably a little bit of over kill for the 8 Volts to the oscillators but that is a good thing, trust me.

The construction note here is to make sure you locate the 10uF 35VSolid tantalum Surface mount capacitors and the 0.1uF surface mount capacitors on both the input and output pins as close as possible to those pins, as shown on the circuit diagram, locate the two regulators close together so they can share C50, C44. Again as shown on the circuit diagram.

(I tend to draw the circuit diagrams as I would lay out the circuit board, makes it easy to do the layout and easy to follow the circuit on the board when fault finding).

The Next part of the circuit is the logic switching circuit, it is designed to be driven from a computer output port, the gates are all used as simple invertors, the 150 Ohm resistors are just there to give a little protection to the inputs, all three gates have there inputs tied to 5 Volts through 3K3 resistors which makes the output of the gates 0 Volts they are all inactive to the respective NPN transistors.

IE. all of the NPN (BC847) transistors are biased off (no current flowing).

If for example the CW input were placed at 0 Volts, ground, the output of U1 A will become 5 Volts, which will forward bias Q10, causing it to draw current through R42 and R43, that will drop the potential of the base of Q9 BC 857 (PNP) causing it to pass current and provide +8 volt supply to the collector, which is connected to the CW Crystal oscillator.

All three inputs work on exactly the same principal (They are the same circuit). Only one input should be taken to 0 Volts (Ground) at a time. Obviously.

Now for the slightly more complicated part of the circuit, the Crystal oscillators.

The first thing you will see is that there are three circuits consisting of essentially the same thing so I expect some one to ask "why build three oscillators?", the reasons for that are as follows.

I hate trying to switch crystals electronically, no circuit that I have tried has been a success.

I have but also hate using one crystal and electronically switching in inductors and capacitors to pull them off frequency, even though the circuit presented essentially does use trimmer capacitors to pull the 8Mhz crystals off there intended Frequency.

Two of the Crystals were the same type I used in the IF filter (RS Components Pno. 472-0253) they are sold in packs of five so you will need two packs to complete the Filter Module and this Module, they aren't very expensive.

The RS Crystals were easy to pull high in frequency but didn't pull Low, luckily I had some older (Dick Smith, Jaycar) Crystals which didn't need much encouragement to pull low.

The cost of the components to make the three oscillators is relatively inexpensive.

Having individual buffer amplifiers after each oscillator makes the output diode switching easier and gives the flexibility of adjusting the output of each individual oscillator if crystal activity is different between the oscillators.

It is important to have a constant level to the Diode ring Modulator.

The first part of the circuit is a basic Colpitts oscillator (Capacitive feedback) nothing incredibly interesting.

R33 is a decoupling resistor it is important with all RF and AF circuits to provide some decoupling from the power supply for each active stage. The decoupling is R33,C38 and C39 (These are in the CW oscillator circuit).

I was asked for circuit point Voltages for debugging. I really don't even think about them anymore having worked in Electronics for some time, at least not for simple circuits like these.

The following is how to arrive at the voltages in the circuit that you should be able to measure without anyone telling you.

Ohms Law, yes you knew it was going to come up again.

First the voltage at the base of Q6, it is supplied by R33, R35 and R36 is also in the mix, for quick estimations ignore R33 it is relatively low resistance and hopefully will only have a low voltage drop across it, so assume at first 8 Volts are across R35, R36. Add the values of R35, R36 together, 5600 Ohms + 4700 Ohms = 10300 Ohms, E/R=I,so

8/10300 = 0.00077669 Amps flowing, now if we multiply that current by the value of R36 we will see the voltage across it (the voltage on the base of Q6) 0.00077669 x 4700 = 3.65 Volts this will not be exactly correct as the base also draws some current but it should be close to what you measure with a multimeter an NPN transistor with 3.65 Volts on the base will have about a 0.6 to 0.75 Volt drop across the base Emitter junction, say 0.75 then 3.65 - 0.75 = 2.9 Volts at the Emitter. 2.9 Volts across R34 (470 Ohms) gives you (E/R=I) 2.9 / 470 = 0.0061 Amps which means the expected drop across R33 (100 Ohm) is 0.0061 x 100 =0.61 Volts.

So now you can do all those calculations again with a voltage of 8- 0.61 = 7.39 Volts across R35, R36.

If the DC Voltages you measure are not in that ball park some thing is wrong, also remember RF current will affect the measurement, but then again if the circuit is oscillating why measure, it works.

The next part of the chain is the Buffer Amplifier BF998, very small but very wonderful. The first thing of note in the circuit is R31, R30, both 47 Ohm resistors, they are stopper resistors to stop the MOSFET BF998 from going into self oscillation at a frequency you cant see, they need to connect directly on the PAD that G1 and G2 are soldered to on the board. I used 0805 surface mount resistors here as they are nice and small (I normally use 1206, larger surface mount resistors as they are easier to work with).

The oscillator output is fed to the Buffer Amplifier through C37 a 33pf capacitor it is small in value to minimize the effect of the Buffer on the tuning of the oscillator, G1 is at ground potential through R32 and G2 is used to set the gain of the Amplifier, you can calculate the voltage on G2 using Ohms Law as in the example for the transistor base voltage, it is around 5 Volts, lowering the voltage by increasing the value of R26 will drop the gain. In general increasing the voltage on G2 increases the gain but there is a point close to supply voltage where the gain will start to decrease again. If you like to experiment use a 20 K Potentiometer / Trimpot on G2 and watch the RF output with a CRO.

I use low value resistors on the Source of the MOSFET as it allows them to draw more current, which means more gain, more output and usually cleaner output, of course this theory has its limits, the maximum Current and Power Dissipation of the MOSFET need to be remembered.

R28 and RFC3 provide a high impedance low resistance load to the Drain of the MOSFET.

Last but most important C33,C34,C35,C36 and L5 form the output matching circuit from the Drain of the MOSFET to the output, 1000 Ohms to 50 Ohms out.(the ARRL handbook has the formulas for calculating the values of the Pi Network, I converted them to a BASIC program on the computer to make life easier).

One more thing, very important, D3 (BA792) it is important to use this type diode, it is made specifically for this purpose, you can purchase them from RS Components.

When the oscillator has Voltage applied to it current will flow through RFC3 and through L5 through D3 and down R37, this achieves two things, first it forward biases D3 allowing it to pass the AC signal voltage and creates a positive DC voltage across R37, reverse biasing D2 and D1,they both should have 0 Volts on their respective anodes, this makes sure that they wont conduct RF signal.

That was a bit long winded but now you know diode switching, MOSFET amplifiers and how to work out your expected voltages and just like your school teacher I wont be repeating myself.

Great now you can build the Module.

I have not included the layout for the PC board (there will be some photos of the constructed Module).

I use single sided PC board, it is available from Jaycar, Dick Smith, I use PC box type construction, you will see this from the Photos, the shielding material for the top and bottom is Milo tin, buy the big can with no ridges in the sides use a can opener ( I use the hand held rotary type) to remove the top and the bottom of the cans off, then a decent pair of scissors to cut straight up the seem, roll it out and you have perfect shielding tin. Warning it is very sharp, watch your fingers.

Layout should be as per the way the circuit is drawn, all three oscillators as close as possible together to make the linking of D1, D2, D3 as short as possible.

A quick note for the Layout, there is a free ware program called Eagle Soft which is circuit drawing and PCB layout Software, I have used it for the Layout of several other smaller and more intricate circuit boards in the Transceiver.

The limitation is the size of the PCB that you can do with the free ware version. It works on Windows prints out the board actual size and give you a way to store some layouts. I simply used a Dalo Pen for this board and the rest of the IF system.

I learnt when looking at the way the Japanese put their radio circuit boards together that you keep the RF and AF stages small and close together on the circuit board, don't worry about making circuit tracks for the supply rails just decouple them and make a hole, use hook up wire to wire up the DC, it gives you much more freedom when doing the layout, keep the DC and switching of DC on one side and the RF stages on the other side.

Component notes

All capacitors 0.1uF and below are Surface mount either 1206 or 0805, all resistors are surface mount 1206 or 0805.

They are all available from RS components or Farnell Components.

They both do mail order over the internet so no problems.

The 10uF Capacitors are Surface mount Solid Tantalum 10uF 35V and are available from Jaycar.

RS and Farnell were a little bit high priced for these last time I looked.

BC857, BC847 are Surface mount available from Jaycar.

BA792 and BF998 are available from RS Components.

74HC00 is DIP14, 7808 is TO-220 and the 78L05 is TO-92 and are available from Jaycar, Farnell, RS Components

Crystals X2 and X3 are the same type used in the Crystal filter module, you will need to two packs (RS Components sell them in a pack of five). RS Components part number 472-0253.

They could be moved higher in frequency easily but were not so easy to move down in frequency. I found an old HC49 8.000Mhz crystal and used it for X1, could have been Jaycar, Dick Smith you will have to experiment on that one.

Trimmer Capacitors came from RS components but I'm sure Farnell and Jaycar have suitable substitutes.

Remember the values of the capacitors tuning the Crystals is dependant on the specific Crystal, you may need to experiment if they don't work.

You will also need a roll of 0.25 mm Enameled Copper Wire, you can go a little smaller if you have to, 0.2mm

The wire is to wind the RFCs and ring mixers throughout the project.

While were on the subject, RFC1, RFC2, RFC3 are all 10 Turns of 0.25mm wire wound on FX1115 ferrite beads.

the FX1115 Beads are available from Jaycar in packs and again are used through this entire project.

The last component is L5, L3, L2 they are a TOKO Inductors 292CNS T1044Z pre wound miniature 2.2uH Adjustable Inductor which I modify and use throughout the Transceiver, at a rough guess through the entire project I have used close to 80 of them, they are very easily pulled apart, small and easy to re-wind.

The hard bit is that they are available through EATON Electrics in Australia but the minimum quantity I was quoted was 400 pieces, that was February 2008 and the price then was AU$0.52 each $208-00 plus $10-00 Shipping fee.

Good thing they are easily modified, if your in a club just get them they are good.

Winding the coils

L2, L3, L5 are all Toko inductors 292CNS-T1044Z (7-96Mhz) available in bulk quantities from Eaton Electrics but are easily modified as follows.

There are can dimples on two sides of the coil that hold the metal cap on.

There are can dimples on two sides of the coil that hold the metal cap on.Slide a screw driver up underneath to raise the metal.

You don't have to remove the dimple, just raise the metal a bit at those points.

With the metal raised at the dimples, pull on unused pins to pull the plastic former out.

Use a good pair of tweezers to pull the top wire from the pin.

It will break easily at the pin joint.

For the oscillator module (1.3uH) remove the top 4 turns (complete top layer).

Once the top four turns are removed just bring the wire back down to the centre, do three or four turns around the pin and solder.

Be gentle, don't push at the pin when soldering just get a big blob of solder on the wire and the pin for several seconds and the enamel will melt off, then run the solder off.

Let it cool and then push it back into the shield can.

You can see I have already removed the unwanted pins, which makes it so much easier for PCB design as they are small inductors - good if you're using a Dalo pen.

IF Module

I have attached two circuits for the Crystal Filter Module, they are on the last pages of this section.

The first circuit is a filter that is in use at the time of writing, it is a 7 pole Crystal filter. The second circuit is an 8 Pole Crystal filter that I am constructing as I write this article, it makes it much easier to describe the construction and adjustment of the circuit.

The 8 Pole filter will become the replacement for the 7 Pole filter that I am using now, it is an upgrade as it should have a sharper response curve which should mean better attenuation of the unwanted side band as well as better attenuation of close unwanted signals.

Both Filters use 8.000Mhz Crystals available from RS Components, I used RS Pno. 472-0253 in the 7 Pole filter, which I see are now discontinued and replaced with RS Pno. 547-6216, I will be using these in the 8 Pole filter.

How did I arrive at the design?

I looked through some older ARRL Handbooks that I own, the most attractive SSB filter shown was a type called a "Ladder filter ", while the information about the filters in the Handbooks was very thin, it looked attractive as it used a quantity of the same Crystals to make the filter, making it possible to use some of the common "Off the Shelf" cheap Crystals.

The Handbooks gave examples of ladder filters made by other Amateurs, which used very different capacitance values.No real design information was presented in the Handbooks other than the mention of impedance being variable depending on the Crystals and bandwidth being inversely proportional to Capacitance values used in the filter.

Test equipment first.

Not being an engineer and having no design information, other than very basic parameters, I needed to devise a way to test and evaluate filter performance, the best way I know of to do that is to use a Sweep Oscillator to sweep across the Filter frequency while being synchronised to an Oscilloscope X axis input. The display on the Oscilloscope will be, Frequency across the X (Horizontal Axis) and Amplitude through the Y (vertical Axis). The Sweep Oscillator is an adjustment aid, it shows the result of your adjustments in slow but real time.When the Filter has been adjusted correctly with the Sweep Oscillator you can do an accurate plot using an accurate Frequency source (Signal Generator) and a Spectrum Analyser or Oscilloscope. The reason for the accurate plot of the Filter is simply to determine what frequencies are needed for the USB, LSB and CW Beat frequency Oscillators.

I have attached a circuit of the Sweep generator I used, it was put together on two PCBs the RF section, Saw Tooth Amplifier and Regulator being on one PC board put together in a PCB box type construction and the digital Saw Tooth Generator PCB screwed to the side of the PCB box. I used both through hole and Surface mount components, with most components coming from my junk box, this was going to be a one time only circuit which I wanted to spend as little money as possible on.

Photos of the Sweep Oscillator are included.

A Brief Circuit description of the Sweep Oscillator circuit.

Firstly the RF Oscillator, I used a BC547 in a Colpitts configuration. The feed back capacitors are formed by stacking two 220pF SMT caps on top of each other to make the 440pF shown on the circuit.

Surface mount resistors and capacitors make it very easy to save space by soldering one component down to the board then soldering another of the same size on top, I have used up to three high but after that it is time to spread them out.

The inductor was made with 0.25mm Enameled copper wire, 29 Turns wound on the Glass from a 5AG fuse, it is about 5mm outside diameter, long glass fuse.

The metal end caps of the fuse are removed by heating with a soldering iron and removing them with pliers, the glass section is then used as the former for the inductor, the turns are held in place with epoxy resin.

I also used epoxy to glue the glass former to the circuit board. (see photos below)

Two trimmer capacitors were used, one to provide a main tune and one to provide a fine tune, the Oscillator sweep function was provided by a high voltage Zener diode (15 to 33V 400mW you can also use 1 Watt Zener diodes, the higher the voltage the lower the capacitance change and the lower the power rating the lower the capacitance), I use them in place of Varicaps. The output of the Transistor oscillator is taken from the collector 100 Ohm resistor through a 0.02uF Capacitor and is buffered by an MPF102 JFET Amplifier, the output taken from it's Source, roughly 50 ohms out.

The Saw Tooth wave form used to drive the RF Sweep and the Oscilloscope X Axis input is generated from a separate circuit board using two CMOS ICs, a 74HC00 is used as an RC Oscillator with the fourth gate used as a buffer, the output of the oscillator is then fed to a binary counter IC, CMOS, MC14020 /4020B. The top eight bits of the 4020 counter are fed to a simple resistive network Digital to Analog converter.

The resistor network is called a 2R network. I like the 2R network when using surface mount resistors because it uses lots of the same value, the 2R value I used was 10k which meant that the R value could be made by stacking two SMT 10K resistors on top of each other (5k), it is almost like cheating.

The output of the resistor network is then filtered with a 0.1uF capacitor to ground and fed to the Op Amp inverting input through a 56K resistor.The Op Amp has a 50 k Trimpot (VR3) attached to the non inverting input, the Trimpot is used to adjust the output Saw Tooth wave form to be centered across the output voltage range of the Op Amp, the wave form should not be clipped top or bottom.(Very important)

The output of the Op Amp is fed to two Trimpots , one going to the Zener/Varicap in the RF oscillator circuit, it becomes the sweep width (Frequency) adjustment, and the other Trimpot wiper is connected through a cable to the Oscilloscope X axis input, this Trimpot is then used as a sweep width control for the Oscilloscope.

As you can see the Sweep Oscillator was changed in design quite a few times on the one PCB.

It was built as a low cost one time only piece of test equipment with components from the junk box.

The small orange and the small brown wires are used to provide 12 Volts to power the Crystal Filter Module under test.

Note: It is a very slow Saw Tooth Ramp and needs to be DC coupled to the Oscilloscope.

Make sure your Oscilloscope has its X channel set to DC.If it is correct the sweep will look continual.(As soon as it finishes to the right it should be starting again on the left, if it isn't doing that either the wave form is clipped or it is not DC coupled.

Note: The LF353 Op amp was just one I had lying around, almost any General purpose op amp will do here. TL082/ TL072...........

Note : If you are keen you can add more resistors to the 2R network and attach the other successive outputs, up to 11 bits, it will give a much finer sweep. I have attached photos of the sweep as seen on my Oscilloscope in the filter adjustment section.

Here's the sweep oscillator.

The Crystal Filter Module circuit description.

At last, the filter circuit description. When I first experimented with the Ladder Crystal Filter design I quickly found out that the books were correct in saying that the input and output capacitances of the Filter network were critical and that they needed to be fed from a resistive load, that is why I have designed the Crystal filter as a module with a MOSFET Amplifier at both inputs and outputs, they Isolate the Crystal Filter network and also feed it with a resistive termination at both input and output and also provide a little gain at the same time.

The input to the IF system needed to be 50 Ohms, that enabled it to be connected to other modules in the Transceiver through a coax cable and also enabled it to match the impedance of the Diode ring mixer I used in the Front End of the Transceiver.

The input to the Filter module is first fed to an 8Mhz Pi Network, 50 Ohms in and out.

The output of the Pi Network is terminated with a 56 Ohm resistor which also serves as the G1 resistor for the MOSFET input Amplifier, Gate 1 of the MOSFET is inherently very high impedance so terminating it with a 56 Ohm resistor effectively sets the G1 impedance to 56 Ohms.

Designing the circuit this way has a few benefits, First the Impedance can be set by the resistor on G1, secondly by using 56 Ohms it allows for stronger signal handling by G1(Lower impedance means lower voltages), thirdly it lowers the gain of the stage, this is a good thing as the Amplifier is meant to be a, low noise, high signal handling, impedance converter (50 Ohm input to 1 K output for the Ladder Filter network).

G2 is fed with a DC Voltage and is used to control the gain (bias) of the Amplifier.

The output of the MOSFET Amplifier is taken from the Drain, it has a 1K resistor to provide a load, it makes a resistive 1K load to the input of the Crystal Filter network.

The output of the Crystal Filter network is terminated with a 1K resistor and fed to G1 of the MOSFET output Amplifier, again, as the input impedance of the MOSFET G1 is very high, the 1K resistor is used to set the impedance and again also provide a nice resistive load for the Crystal Filter network.

The MOSFET output Amplifier has a 500 Ohm (Two 1K resistors in parallel) resistor in the Drain circuit as a load, the Drain output being fed via a coupling capacitor to a Pi Network which is used as an impedance converter, 500 Ohms at the Drain side and 50 Ohms at the output.

The Crystal Filter network is a Ladder network as shown in the ARRL handbook, it has the Crystals in series with each other and a capacitor to ground at each junction. The Values that I arrived at for the Particular Crystals I used was 33pF.

The terminating capacitors are variable 10-100pF and are used to adjust the shape of the filter, they are critical. (I used Trimmer Capacitors from Jaycar)

Note: Not all Crystals are the same and not any Crystal will work in this circuit.

To select Crystals for the filter, I set up an Oscillator (I used the Sweep oscillator with the input coupling capacitor,33pF, lifted and the Crystals tacked between the open end of the coupling cap and ground)

give each Crystal 5 Minutes to settle then note its Frequency, label each Crystal and sort them out.

The Crystals I used all were within 100Hz of each other and I placed them in the circuit in ascending order.

(I have no Idea if that has anything good going for it, it is simply what I did)

Frequencies of the Crystals used are shown on the Filter shape diagram.

Adjustment of the filter.

The first thing to do is to get the sweep Generator operating at 8 Mhz,set the Fine tune trimmer capacitor to 50 %, adjust the Sweep Frequency width Trimpot to full. (full Saw Tooth voltage on the Zener diode or Varicap which ever you used).Note : Use a Spectrum Analyser or an accurate radio to tune the oscillator as it will be sweeping and a Frequency Meter will be useless.

Connect a coax cable from the output of the Sweep Oscillator (RF) to the input of the Filter Module.

Connect the output of the Filter module to the Y input of your Oscilloscope, at this point leave the Oscilloscope in normal Mode, if the output is near 8 Mhz you should be able to see an 8 Mhz RF trace pulsing in amplitude, either way adjust the main tuning Trimmer Capacitor very, very slowly until you

see the RF envelope come up in amplitude, adjust your vertical sensitivity (Oscilloscope) to get a decent size trace on the oscilloscope and then Adjust the input Pi Network inductor (Filter Module) for a peak in amplitude, next adjust the output Pi Network (Filter Module) for a peak in amplitude.

Connect the Saw tooth output from the Trimpot on the Sweep Oscillator Module to the X Axis input of your Oscilloscope, set the Oscilloscope up for, external sweep, DC Coupling, you should now have a very slow sweep across the face of the Oscilloscope, adjust the X axis Trimpot of the Sweep Generator to get a full sweep, you will probably have to adjust your horizontal sweep position to center the sweep.

If you adjusted the RF output of the sweep oscillator correctly you should now have an RF envelope on the screen, Adjust the fine tune Trimmer Capacitor (Sweep Oscillator) to center the envelope.

Adjust the two Trimmer Capacitors in the filter module to get the maximum RF output first then Adjust for the cleanest envelope shape. (The Lowest size ripple)

That's the adjustment done, take away the sweep oscillator, and now use an accurate RF signal generator and a Spectrum Analyser (or receiver if you have one with an accurate S meter, remember this is only a relative measurement to get the shape of the filter). I used 100 Hz step sizes from my signal generator to manually do the plot on some graph paper. Hopefully after all is said and done you have a filter shape like mine and can use the same BFO frequencies.

If you look at the plots of the seven and the eight Pole filters you will see clearly that the eight pole will be a great upgrade for the Transceiver.

This is the Oscilloscope display with the Sweep Oscillator connected and the filter adjusted for best output, after this I disconnected and did the manual plot. This is the 8 Pole filter.

Luckily the camera took a long exposure, that is why it looks like several traces, in real life I needed to turn out the lights and turn the intensity up to see the trace as it is very slow, less than 1 Hz and I have a standard CRO.

Construction notes for the Crystal Filter Module.

The Crystal Filter Module should follow the same construction practices for all RF Circuits.

The input should be at one end of the circuit board and the output should be at the other end, it is very important that the Crystals be laid out this way to avoid RF leakage between input and output.

I have attached photos of the Filter Module through the construction stages.

I made a few mistakes in the layout shown, I forgot the input coupling capacitor, very important, I cut the track between the Pi Network input side and the input pad, then soldered in a Surface Mount Capacitor across the gap.

The layout was made for SMT HC49 Crystals which I found out later were through hole types, easily fixed, drill holes.

I also managed to do the layout with one of the MOSFETs mirrored. The MOSFET package is very handy for this mistake. Place the MOSFET package upside down in the correct spot on the PCB (I use the point of the scribe to push down on the black package) then with the point of a pair of tweezers or a small instrument screw driver, gently push the pins that are now pointing up in the air down, when all four are pointed down, put some solder on the tip of your iron and while still holding the package down with the scribe, tack solder one pin, you can now remove the scribe and solder the remaining pins in place correctly and then re-solder the tack solder joint. The same technique as above works well for soldering most Surface mount components to a PCB.

Surface Mount Resistors and Capacitors are 0805 and or 1206 sizes and are available through RS Components and Farnell Components, Crystals are available from RS Components (I was lucky, I bought two packs of five and managed to find 8 of them within 100Hz of each other 2 Crystals were well outside that range, at around $5-00 +GST per pack of five it might be wise to buy three packs).

The BF998 MOSFETs are available from RS Components. Trimmer Capacitors were from Jaycar.

Milo is available from the supermarket buy the non ribbed tins (or if you have friends that drink it get the tins from them. Blank PCB Jaycar or Dick Smith. (I find the 300x300mm the most economical).

I made the layout using some Freeware available on the internet " Eagle Soft Lite ", it is limited and a little tricky to master the software (I found) but it allows you to print out the layout in actual size and to mirror the print. I used a PCB marking pen to make the layout on the PCB but as the connections were all for surface mount components (mostly) I used a Metal Scribe to mark the circuit board where the surface mount components were to be located, press the point in gently to make a dot (The printed layout was taped to the PCB copper side), this made it a lot easier to do the draw with the "Dalo" pen.

Even after I had scrubbed the PCB with dry, non soaped steel wool, ready to use the "Dalo" pen the scribe points were still clear. (You might be able to see them in the Photos).

When the circuit board was finished the sides were filed straight and then I cut Tin from a "Milo" tin to make the enclosure. (See photos)

8 Pole circuit:

(Right click the circuit above and view in a new window to see it full size).

The 8 Pole filter is now in the Transceiver and working great, it has the same BFO frequencies as the seven pole filter. Here's the old 7 pole version.

Complete 8Mhz IF System, USB, LSB, CW for HF Transceiver.

Part 3 of 3

This is part three of the IF system, it describes the construction of the Main IF Module.

If you have followed the articles so far (Part 1 and Part 2) you should have already completed the BFO Oscillator module and the Crystal Filter module, so this part will complete a working IF strip.

Circuit design.

I'll start with the RF input of the IF Strip , it is actually both the input and output, why?, it means only one coax cable is needed to join the RF input / output module to the IF Strip, the IF input / output goes to a double balanced diode ring mixer in the RF Input/Output Module through a Pi Filter, the ring mixer is a Bi directional circuit also, at the other side of the mixer the band filter / RF amplifier circuit is diode switched to be both Receive input circuit and RF filter / Pre-driver module for the transmit side.

Back to the IF design. The input output goes first to a diode switching arrangement, in RX mode 12Volts RX is fed through R27 and forward biases D4 with current flowing through the 1K resistor to ground at the input of the filter module, the positive voltage developed across this resistor is used to reverse bias D5 and D3 (+12V TX is at this point zero volts as we are in receive mode), at the output of the filter module D1 is fed with 12 Volts RX from R51 and passes current to R12, again the voltage developed across R12 is used to reverse bias D2 (+12V TX is at this point zero volts as we are in receive mode).

The signal path in receive mode is then, through C47 through D4 to the input of the crystal filter module, the crystal filter module is powered by +12 Volts constant and is powered during both Transmit and receive modes, the filtered output of the crystal filter module is then fed through D1 to the first IF amplifier through the matching Pi network , the Pi Network takes the 50 Ohm output of the Filter Module and transforms it to a much higher impedance more suited to the G1 impedance of the Dual gate MOSFET.

G2 of the Dual gate MOSFET is driven with AGC voltage to vary the gain of the Amplifier (Approximately +10V max gain and 0 Volts minimum gain). The Receive 12 Volt rail is fed to the Drain of the first IF through L2 a 33uH choke, low resistance to DC but a very high resistance to the 8 Mhz signal , the drain output impedance is matched through the Pi network approx. 1K and stepped up for the G1 of the second IF Amp. to 3300 Ohms, designed with a loaded Q of 10.

The 2nd and 3rd IF amps are the same design with the exception of the Pi network at the output of the 3rd IF amp, the output side of this Pi network is 50 Ohm impedance to match the double balanced ring mixer which is used as both detector and modulator, its bi directional properties are used to full advantage in this circuit.

In receive the high impedance (Drain) side of this Pi network is picked off by a low capacitance (33pF) capacitor and fed to the AGC amplifier, another MOSFET witch is used as a broad band RF amplifier and followed by a voltage doubler rectifier circuit, it is filtered and then fed to the DC Amplifier, the DC Amplifier uses a 1N914 diode forward biased to get the Transistor Base voltage very close to its turn on voltage making it a very sensitive DC Amplifier. The supply rail of the DC amplifier is regulated at 10 Volts by the Zener diode Z1 (10V1 1 Watt), this gives it a voltage swing at the collector of roughly 10 Volts no signal and 0 Volts full signal, exactly what the G2 of the MOSFET IF Amplifiers require. The S meter circuit uses two trimmer potentiometers, VR1 is used to set the Plus side of the Meter to the same as the collector voltage (there is a small difference at no signal as the bias just switches on the transistor) and VR2 is adjusted so that when the collector is at 0 Volts (full input signal) the Meter reads full scale.

The ring mixer is fed with the BFO voltage through a resistive attenuator network, the output of the mixer is then fed through a Pi Filter to remove all the RF content and is then fed to the AF section of the circuit.

The AF Section.

In the AF section of the circuit several CMOS switches are used, in receive mode the C switch is on and passes the AF from the mixer to a Buffer Amplifier and then through several AF Low Pass filter networks.

The filters were arrived at by ear, mine, they provide a noticeable difference to the AF noise of the IF amplifiers as well as improving the audible interference from nearby signals.

In transmit modes C switch is always switched off but either A or B will be switched on depending on the mode you are in. When SSB is in use (no voltage from CW send switch but 12 volts TX present) then switch B is enabled and switch A is disabled allowing the output from the Microphone Pre Amplifier to be passed through to the mixer. Note the OP AMPS and AF Amplifier are powered by 12 volts constant and are always powered.

In CW mode switch A is on and switch B is turned off by Q1 which is biased on by the +12V from the Send switch, switch C is off as there is no +12 V RX during TX mode.

with switch A on VR1 is set to pass a DC current to the Diode ring mixer, it should be adjusted to maximum RF output from the mixer and then backed off till the output drops just slightly.

CW keying is performed at the RF Power Amplifier Module.

Transmit design.

The output of the mixer during transmit is picked off from the Drain of the third IF Amplifier by a 33 pf Capacitor and fed to G1 of the TX Amplifier, yet another dual gate MOSFET. The output of the TX Amplifier is formed across a resistive load, 500 Ohm and a Pi Network is used to transform the 500 Ohm impedance down to 50 Ohm for the Filter input. A Pi Network resistive attenuator is used to attenuate the signal from the TX Amp. to a good level for the input to the filter as well as the final output to the RF Filter Module (Double balanced ring mixer), as the DC drain voltage is still required here to forward bias the switching diodes D3 and D5 the resistive attenuator has a capacitor to ground to pass the AC component and stop the drain voltage from being shorted to ground through the low value resistors.

In terms of diode switching the diodes D3 and D5 are forward biased by the TX +12 Volts which is passed through the Drain resistor of the TX Amp., voltage developed across the input 1K resistor of the Filter Module is used to reverse bias D4 (RX +12V is now at 0 Volts as we are in TX Mode), the RF output of the TX Amp. is then passed to the Filter Module input. At the output of the Filter Module +12V TX is used to forward bias D2, the current passed develops a voltage across the 1K resistor at the output of the Filter Module which is used to reverse bias D1 (RX +12V is now at 0 Volts as we are in TX Mode).

That's it for the circuit theory.

Construction.

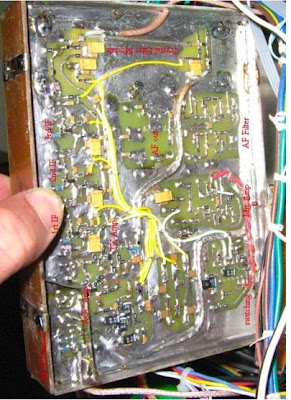

I have attached the circuits and some pictures of the constructed Module, please look at the construction method, PCB box, also look at the layout, RF side has a logical flow input to output and is much the same as the circuit diagram, RF wiring is made with Teflon coax (you can buy it from Jaycar in a made up SMA lead 3 Metres for $24.95 when I purchased it last) on the circuit board remove the outer Teflon coat and solder the braid to the PCB, makes for a well shielded connection.

Shielding is done on my module with Milo tin cut to correct size strips (use the non ribbed Milo tins) holes are drilled at points along the shielding to make points where tinned copper wire can be soldered to the tin and brought through the PCB both as an earth point to the board and an anchor point for the shielding tin.

Components used are Available through a combination of RS components, Jaycar, Farnell Components.

All the PCB artwork for the main module was done with Dalo Pen.

Alignment.

The Alignment of the completed module is very simple.First connect and adjust the S Meter as suggested in the theory text (Must be in RX mode) and then connect a low level 8.000 Mhz RF signal source to the input.(you can use the BFO module as the signal source (CW Mode) with a switched step attenuator) adjust the output so the meter just moves, then adjust all of the RX Pi networks for a peak in meter deflection, as the meter deflection increases reduce the RF input. In transmit mode you will need the BFO module connected up to the Main IF module and set the modes to transmit as well as CW, the output of the IF strip can now be connected to a general coverage receiver or Oscilloscope, Adjust VR1 in the AF circuit to Max voltage (highest current to the ring mixer) then adjust the TX Amp. Pi Network for maximum output then go back to VR1 in the AF section and back off until the RF output begins to drop below max.

That's it, go build.

Construction notes

Build your circuit board first and test it.

If it is all good then cut four sides for the board make sure they are a little higher than the highest component on the board.

I tin the copper side of the side PCs completely.

Then one side at a time 90 degrees to the PC board get the first one in the correct position and solder to the main PC (The main PC must have an earth land completely around the outside to solder the sides to.

Drill the holes needed for the wiring to come out (I use a lot of teflon coax (Jaycar 3M lead) and teflon wire) you need to be careful where the wires exit sharp edges of PCB.

To shield the open top and bottom of the boards I use the Milo tin (yes start drinking it or if you have friends who like it steal their can) its the perfect material, remove the top and bottom of the cans with can opener, roll out the tin, then mark around the PC box with it laid flat on the tin and mark another 4mm outside that to fold over, thats the top and bottoms done.

Next is the mounting as you could see I mount most vertically, drill holes in the bottom side, but here is the good part, scrape a nut (I use 3mm screws and nuts) put the screw from the outside and the nut on the inside then solder the nut to the inner PC side.

If you make the Radio up in modules like that, test each module as you build, the construction might look harder but it flies along and you can walk away from it take a break and come back to do another module.

I strip the shield from the teflon coax and solder the braid to the earth of the PC routing it to where I want it to go.

The RF section is laid out in the same maner as the circuit ie: Smallest signal in one end and Largest signal out the other end furthest away.

The Audio section, who cares, find a spot on the circuit board and dump it there. DC and AF connections can be wired accross the board.

RF should follow a set path and be well shielded.

Note: The diode modulator got shielding above and below because of the high oscillator injection (the oscillator is a sepperate module for that reason)

I used Milo tin bands around the sides of the PC box for an earthed solder point to the top and bottom shields.

You should be able to see the long nuts I sanded tinned and soldered to the boards.

The circuit board was done and printed from Protel dos version drilled from the print but the Circuit board was done with a Dalo Pen (PCB pen Jaycar Dick Smith, its a little tricky but once you work out the Dalo pen they work fine, good for one offs)

Computer Module

When I build the Microcontrollers for my projects I build two at time (I hate building them) so at any point I have one built and ready for the next project I found my spare the other day.

It is a fairly big module but has grown in design with my experience.

IE computer reset on the Z80 can be a little tricky when you have capacitor backuped up RAM.

I eventually added a comparator circuit that runs from a super cap it self and hits the reset if the Voltage drops. Use a 74C922 IC as a dedicated keypad controller. Ended up with 4, 8 bit output ports and 1, 8 bit input port.

Its a little arcaic compared to some of the Microcontrollers I have worked with in my working life. (210 Pin ICs with multiple I/o Ports, multiple ADC channels).

But the Z80 is easy to pragram (Machine code) well documented, and still made even today.

I use the new Generation CMOS Z80, 10 Mhz, there a little more expensive than the HMOS that you could buy at any electronics store for $2.50 in the late 80s but they are a lot less noisy RF wise. Still need to be boxed and shielded well.

The firmware is just a 32K hex file that dumps straight into a 27C256 and you're away. I wouldn't bother writing out the assembly I'm only half way there on my own records.

The assembly is spread over 3 excersise books now, I keep meaning to write it all out as it is in the Eprom but I half way it was another job I was going to do on these holidays but I think I'll let it slide for a rainy day.

The board, hand drawn with a Dalo pen.

I used free software to do the circuit boards for the smaller module boards, the software only supports small circuit board sizes. I used to sweat when using the Dalo pen but then realised that any unwanted little joins can be scraped off with a scribe when the ink dries a little.

The PC box shielding is a must for the computer module as are ferrite rings or beads on all external wiring.

Audio

Now all I have to do is guess the correct value for the Mic amp, test it then put it all back on the air only to hear winges of, I can hear back ground noise and room acoustics. Can't please everyone.

Note that Peter changed R33 on the Audio section (Microphone Amp) from 47K to 100k. The microphone seems a bit deaf.

-----

Well, I was pleased with the audio. Anyhow, all credit to Peter VK3EPW, he's planning to write this up for Amateur Radio magazine.

There's some very interesting construction techniques here I thought.

I'll pass on any comments to him if you want to make contact.

7 comments:

That's an incredibly impressive piece of work.

I don't think I'd have the patience to produce all the PCBs to make such a neat job. I'm more of an ugly-tangle builder, especially of RF circuits.

A Z80 controller, that's pretty hard-core. I still have fond memories of the Z80 instruction set... I must admit that I preferred the 6502, something about its simplicity I think.

Agreed. Nice work.

I liked the 2650 chip, TI, I think.

Auto increment/decrement, on br. inst..

Peter VE3GYY

Just heard VK3EPW calling CQ CW 80m. Googled the call and landed here. What a comprehensive and impressive homebrew rig. I wonder if he was using this txcvr tonight. Hope he was!

73 Paul VK3HN.

Hey Paul,

I'm a big fan of your work. https://vk3hn.wordpress.com/category/homebrew/

We should meet up soon as I now live in VK3.

73

Peter

Hi Peter

I was just amused by your report of OTN Dinner, I was licensed in 1977 but dropped it for a few years. I am an OT now too. OMG!

Thanks for your kind comment, I always stay tuned whenever you come on ABC so I am a big fan of your work and have been for a long time!

Please email me via QRZ.com and we may be able to meet up in a park for some portable fun sometime, before it gets too cold.

VK3HN.

Hi Peter,

EC5ACA Juanjo fm EA5 here. I cannot see the schematics you linked, it keeps saying "server problem". Is there another way to see them? TIA

Juanjo,

I'm sorry about that. The circuits were in my Apple iDisk but I think that service has gone.

Peter

Post a Comment