Ever since I attended a workshop on stepper motors at Dural conducted by Peter VK2EMU I've been watching for the site of an inkjet printer by the side of the road and this morning there was a rather wet Canon calling me...

Ever since I attended a workshop on stepper motors at Dural conducted by Peter VK2EMU I've been watching for the site of an inkjet printer by the side of the road and this morning there was a rather wet Canon calling me...After about half an hour of messing about the device was a wreck but these printers sure are a treasure trove of useful parts for the home robot maker: cogs, rollers, pulleys, switches, sensors and motors. Regrettably, this model doesn't use stepper motors but rather they seem to be DC motors with a rotary encoder linked to each one.

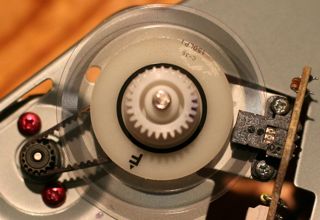

The encoder disk is amazingly fine and it passes through an optical reader which I guess is rather like the encoder in a mouse. The markings are 7120 G516 but so far I haven't found a data sheet for them. The board has 4 wires coming from it so there's not too many options.

Anyhow, despite my disappointment about the lack of steppers, I did score four very nice DC motors that seem to run well on about 3 volts and will be suitable for computer control or making little robots like this.

It's truly amazing the amount of perfectly good electronics that are available for free at council junk collection times.

2 comments:

I know where those shaft encoders are going :)

Yeah ratting dumped electronics is a great way to get electromechanical parts. If nothing else just studying the guts of consumer devices can be very enlightening.

I picked up some older-style CD player optics from the Dural T&T last year that were very interesting. They had a 2-D voice-coil lens positioning system, a half-silvered mirror, two other lenses, an IR laser diode, some photodiode package that appears to have multiple elements in it and two DC motors with limit switches.

The lens positioning system was the most interesting, the lens platform was cantilevered on four springy wires which fed the coils, one bipolar for Z and one quadrapole for X. There was a coarse tracking worm-drive with anti-backlashing mechanics, all moulded in plastic, including the springs. A truly amazing piece of polymer engineering in its own right, but the entire system was extremely impressive, especially considering what it must have been priced at.

That cable-pulling robot is cute. Never thought about building a non-microcontroller based robot, but that video has inspired me. Might use the motors I ratted from the CD players, but they will likely need reduction drives to offer any significant torque. He appears to have used modified servos.

Thanks Alan,

Yes a rotary encoder sounds like just the thing to go with a DDS eh? Just have to figure out how to read the thing.

See you on Sunday.

peter

Post a Comment